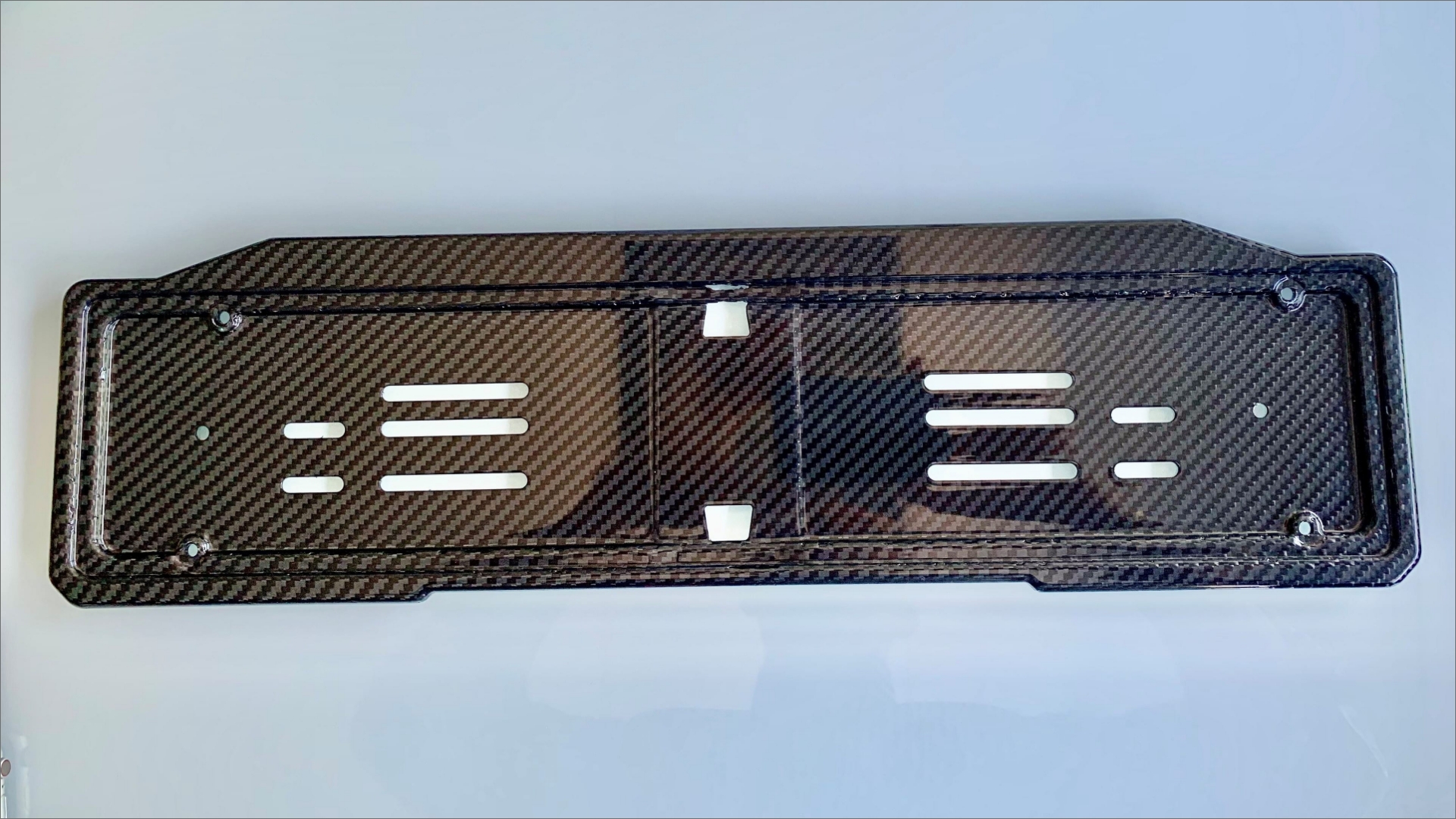

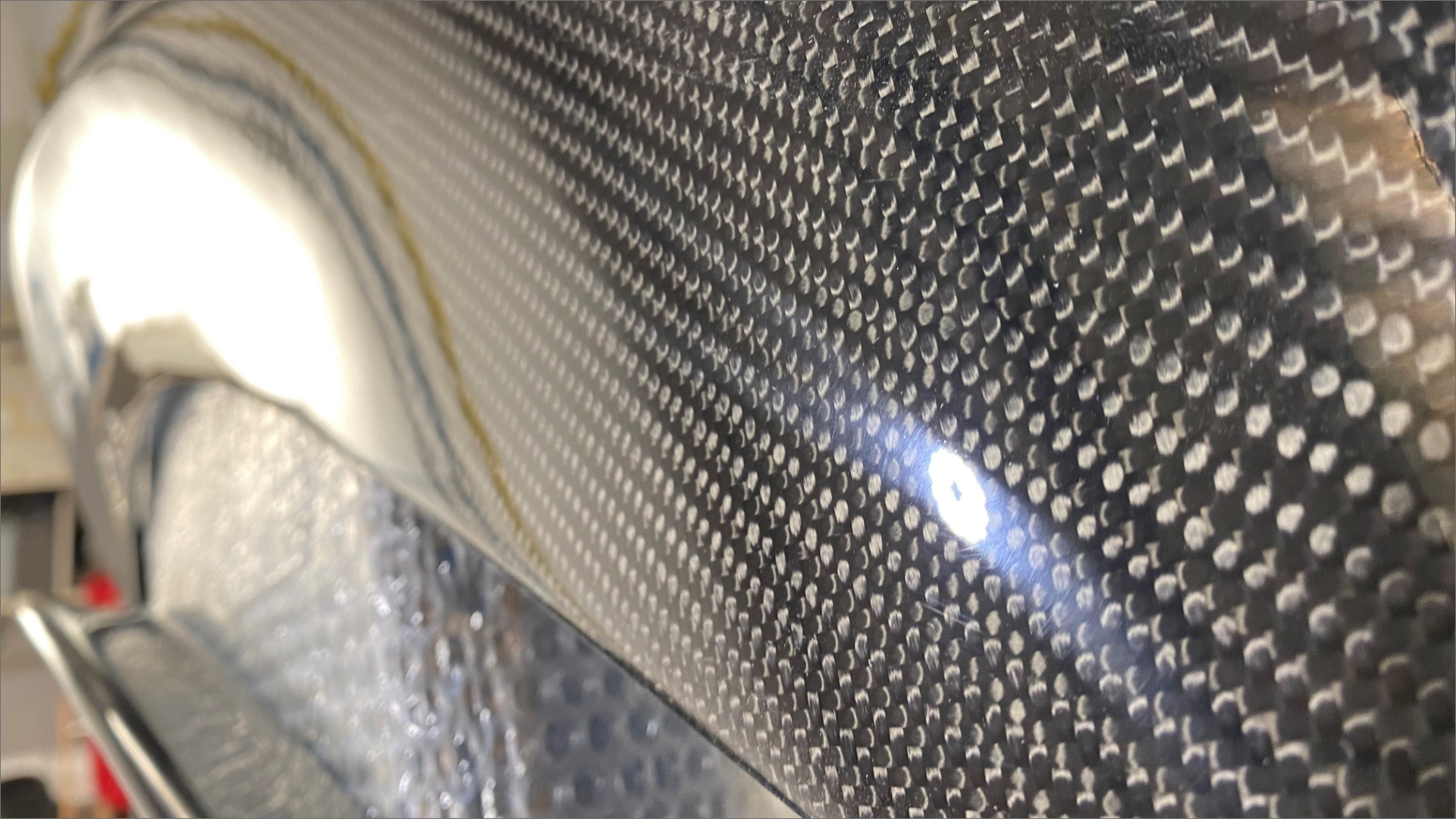

Fibra di carbonio:

CAB possiede un reparto dedicato alla fibra di carbonio dove svolgiamo lavorazioni di levigatura, personalizzazione delle parti in fibra di carbonio, verniciatura e lucidatura per nostri clienti del settore automobilistico e non solo.

CAB possiede un reparto dedicato alla fibra di carbonio dove svolgiamo lavorazioni di levigatura, personalizzazione delle parti in fibra di carbonio, verniciatura e lucidatura per nostri clienti del settore automobilistico e non solo.

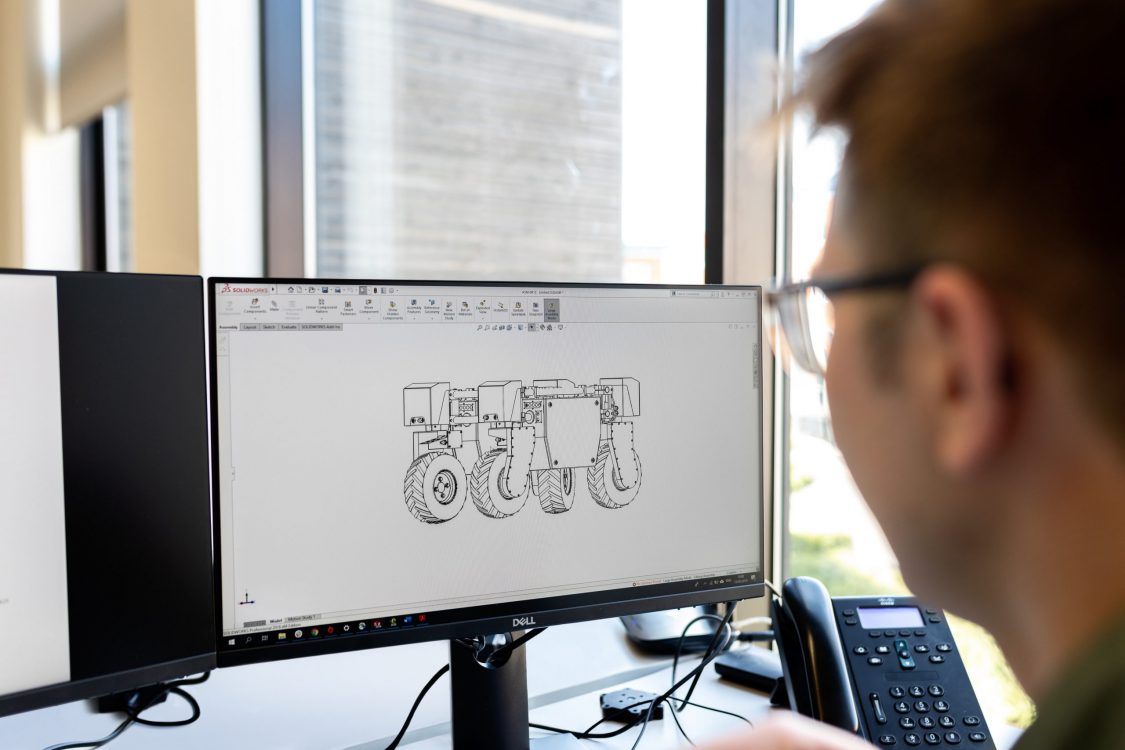

Prodotti da additive manufacturing

CAB realizza la verniciatura su prodotti realizzati tramite additive manufacturing ed è certificato per questo processo.

CAB realizza la verniciatura su prodotti realizzati tramite additive manufacturing ed è certificato per questo processo.

Tipo di materiale:

- Alluminio

- Acciaio

- Titanio

- Fibra di carbonio

- Prodotti da additive manufacturing